About Hanger Bearings

The purpose of Hanger Bearings

In the blast cleaning industry, either Blast Machines or Air Blast Rooms many tons of abrasive have to be recirculated every minute. Screw conveyors are the most common practice and if the equipment is over 20 Ft long a screw conveyor requires a Hanger Bearing. Not only because the standard 5” pipes used for screw conveyors are available in 20 ft length, a longer screw would deflect too much and touch the hopper’s wall where it is installed. Some Air Blast Rooms are 100 Ft long, such long screw conveyor does require four Hanger Bearings.

Often the hopper restrictions don’t allow a screw conveyor segment to be replaced in one piece, by introducing a Hanger Bearing it is convenient to install two sections of such screw conveyor.

Why Hanger Bearings fail?

The main reason for short life of a Hanger Bearing is a misalignment. If a screw conveyor has one or more Hanger Bearings aligning all the bearings is critical. If the bearings are not in line from the first day of operation all the bearings will be subjected to side loaded forces. With time the misalignment does grow and bearings will fail prematurely.

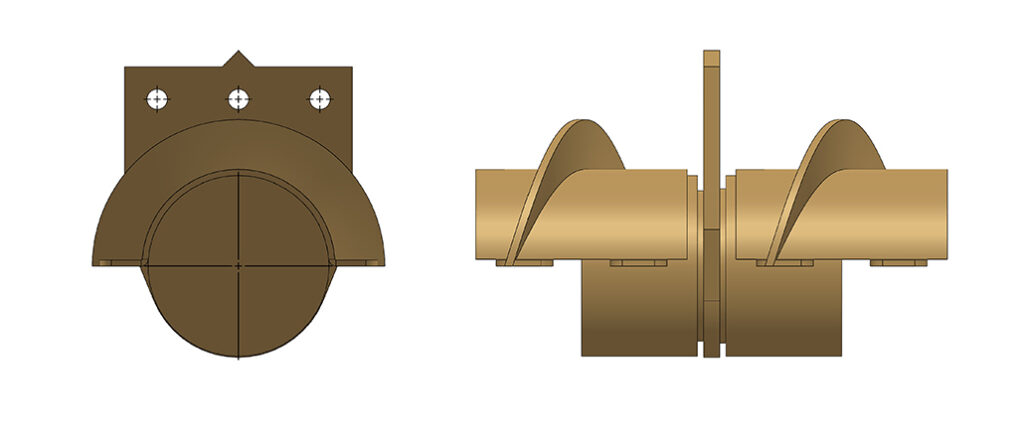

The picture below does show a point at the top of bearing plate which does indicate the center of Hanger Bearing. It will help you to align the bearings correctly.

It is a bad practice to overload one section or a part of a screw conveyor, even aligned bearings life will be shortened. In such case metering plates over screw conveyors are used.

It important to have stiffeners in the section of a hopper walls in the area where Hanger Bearings are installed. The stiffeners will prevent the hopper walls from flexing and prevent the Hanger Bearings being misaligned.

The rule is to not overload a screw conveyor, only 30% of the flighting should be used to move the abrasive. The best practice is to have metering plates over the entire length of a screw conveyor.

In Blast Machines the Hanger Bearings can not be installed in the blast chamber area, there is no positive way to protect them from abrasive flying at 300 Ft/s in every direction. Install Hanger Bearings in vestibules as far away from blast as possible.

Why the Rigid Hanger Bearing is the best design?

This type of bearings correctly installed do give the maximum chances for them to be aligned for years. There is minimum allowance for misalignment from the very beginning.